Measurement and evaluation services for static and dynamic errors in numerically controlled machines

Measurement service offering:

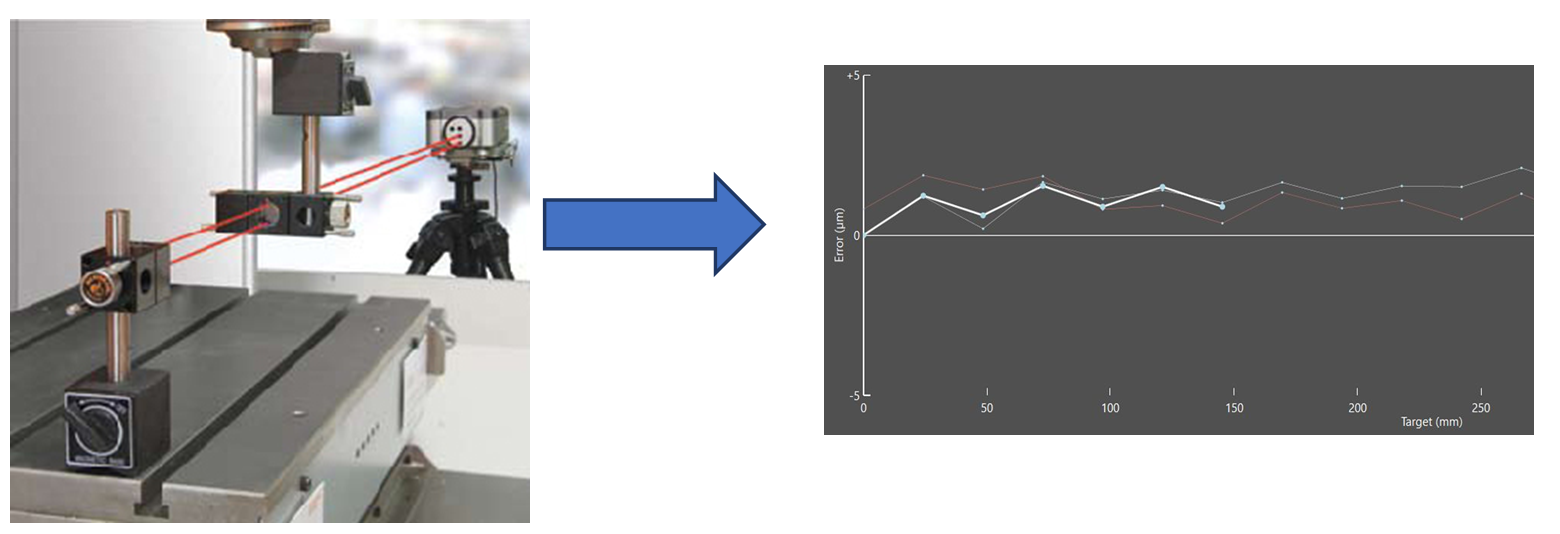

- Static error measurement service for numerically controlled (CNC) machines using a Renishaw XL-80 laser interferometer

- Linear measurement – accuracy of positioning along a linear axis (1 nm resolution),

- Angular measurement – vertical inclination and horizontal deviation along an axis

- Straightness measurement – errors in planes perpendicular to an axis

- Rotary axis measurement – angular positioning accuracy of a rotary axis

- Perpendicularity measurement of two nominally perpendicular axes

- Generation of error tables and error compensation based on measurements.

The price for measuring the accuracy of positioning of one linear axis for typical Cartesian machines is 1000 PLN. Other measurements are priced individually depending on the structure and size of the device.

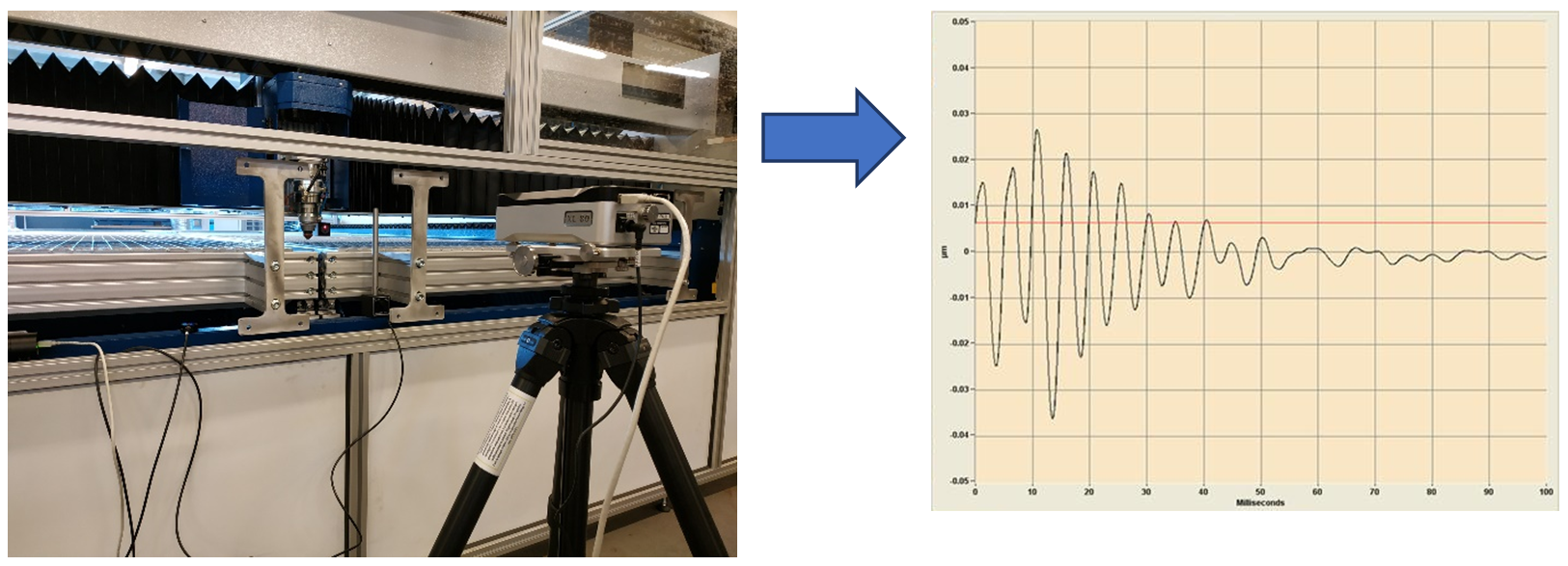

- Dynamic error measurement service for numerically controlled (CNC) machines using a Renishaw XL-80 laser interferometer.

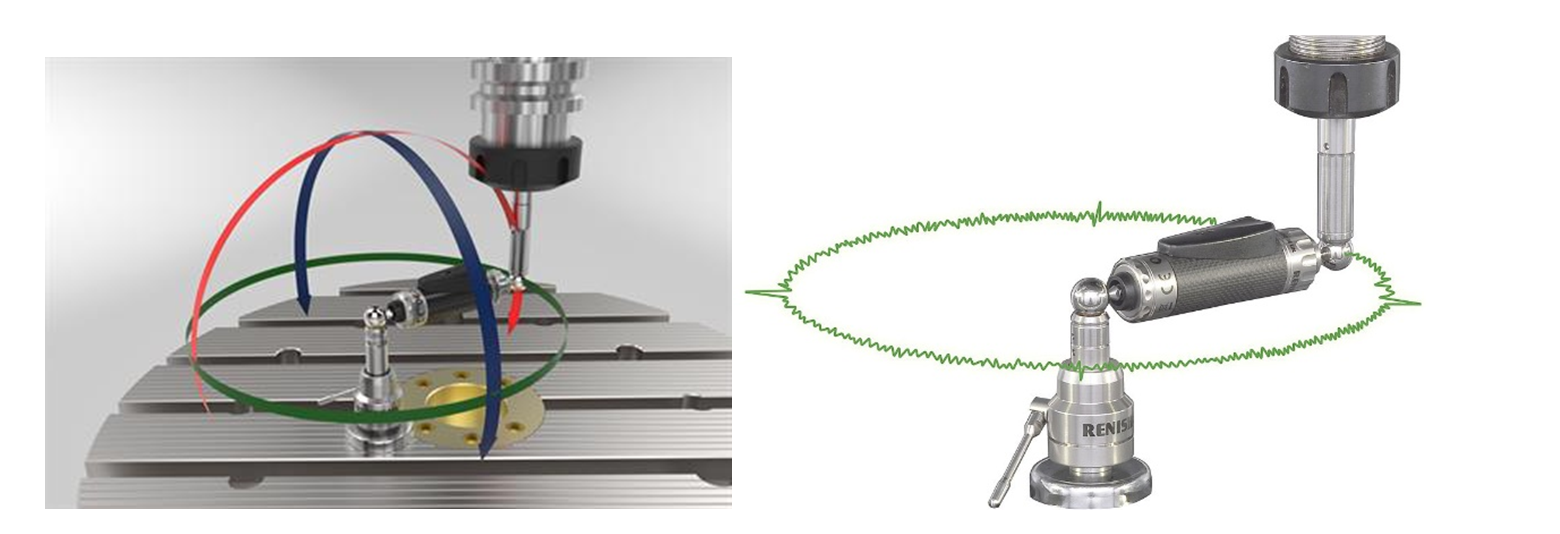

Continuous measurement of the position of an axis or other structural feature. Information can be obtained on axis tracking errors, deflection and vibration of machine structures (e.g. beams on gantry-type machines). The XL-80 measuring device is additionally equipped with analogue and quadrature input signals and a digital trigger input to synchronise the readings with the customer’s machine control system. - Measurement and error assessment service for numerically controlled machines using the Renishaw QC20-W Ballbar.

Measurement involves making a circular trajectory and recording the deviation from a specified circle. - Scaling mismatch

- Perpendicularity deviation

- Straightness deviation

- Cyclic error

- Backlash

- Heading error

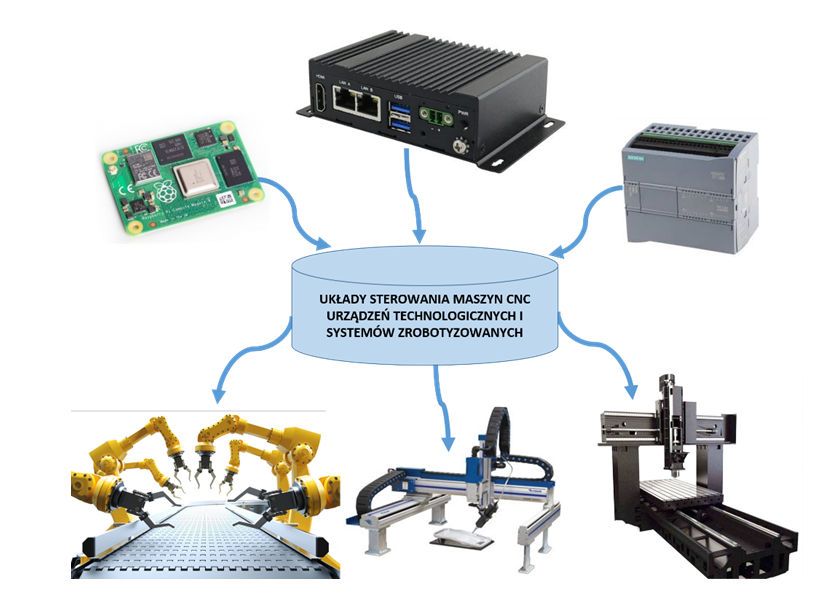

- Research and development services for the design and development of control systems for machines, technological equipment and robotic systems.

We offer research and development work to develop new controllers for numerically controlled multi-axis machines and specialised machines and robotic systems. In particular, we have knowledge and experience in optimising control systems for electric drives, optimising trajectories of multi-axis devices, methods based on artificial intelligence. We have experience in developing and implementing PC-based control systems, PLCs, microprocessor systems. We have conducted research and development work in communication in machine control systems based on Powerlink and EtherCAT real-time buses. We also offer the implementation of modifications and extensions of the functionality of the customer’s control systems. With our knowledge, experience and access to advanced research equipment, we offer innovative control systems tailored to customer needs. The price of these services will be determined individually based on the planned scope of work, the number of people involved, and completion time.

We can identify the following errors in the selected plane collectively from the measurement:

We can identify the following errors in the selected plane collectively from the measurement:

For large machines, it is necessary to carry out more tests to cover the whole working area. The Ballbar test is less accurate than interferometer measurement. It is recommended to carry out an initial error assessment with a Ballbar and then accurately measure selected errors with an interferometer, especially for machines with a large working area. Combining three measurements in the XY, YZ, and ZX planes is possible to determine volumetric (spatial) errors.

The price of a standard Ballbar test, including error report generation, is 1000 PLN. Additional measurements (e.g. for machines with a large working field), volumetric measurements, the development of compensation strategies are subject to additional charges priced individually depending on the complexity of the work.

Contact person:

Krystian Erwiński, Phd

erwin@umk.pl

Contact person:

Marcin Paprocki, Phd

marcin.paprocki@umk.pl

Measurement services for energy efficiency of power electronic converters and vibration and acoustic noise

List of available test equipment:

- Programmable DC voltage sources:

- Keysight N8742A – 3,3 kW (0÷600 VDC, 0÷5,5 A);

- Ametek Sorensen DLM 600-6.6E – 4,0 kW (0÷600 VDC, 0÷6,6 A);

- Keysight N8762A – 5,1 kW (0÷600 VDC, 0÷8,5 A);

- DC/AC active load 3 x 4,5 kW:

- 3 x Chroma 63804 (0÷350 VAC, 0÷45 A);

- Power analyzer:

- Yokogawa WT5000 (6 channels, 0÷1000 V, 0÷30 A).

- Wideband oscilloscope with a set of probes:

- LeCroy HDO4054A (4 channels, 500 MHz);

- 4 x Pintek DP-200PRO insulated voltage probe (±800 V, DC÷200 MHz);

- 3 x Pintek PA-699 current probe (± 40A, DC÷1.5 MHz);

- Noise and vibration measurement and analysis kit:

- Brüel & Kjær Hand held analyzer Type 2270 ;

- 2 x microphone Type 4189;

- Laser tacho sensor Type 2981;

- Type 4533-B accelerometer (0.2÷12.8 kHz);

- Type 4519 accelerometer (1÷20 kHz);

- Type 8344 accelerometer (0.2÷3 kHz).

Research services offered

- Measurement and analysis of the energy efficiency of power conversion devices (mechanical and electromechanical systems);

- Synthesis and performance analysis of control algorithms in power electronic converters;

- Development of prototype microprocessor systems for application in converter and drive systems;

- Measurement and analysis of generated vibrations and noise in electromechanical and mechanical devices;

- The service of making available the research and measurement apparatus located at the equipment of the laboratory of electrical converters and drives.

Contact person:

Łukasz Niewiara, PhD

lukniewiara@umk.pl

ul. Wileńska 7, 87-100 Toruń

ul. Wileńska 7, 87-100 Toruń